Creating a Smarter Tunnel

TunnelWatch® is more than a conveyor controller. It’s a new breed of car wash tunnel control software that keeps you in touch with your tunnel from virtually anywhere. Now more than ever, TunnelWatch gives you unprecedented control over your tunnel equipment, helping you lower costs, enhance wash quality and achieve greater customer satisfaction.

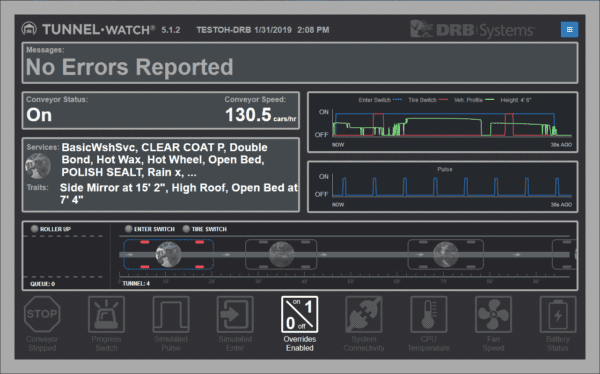

Quick Status Screen

TunnelWatch 5 features a new Quick Status Screen. This allows you to view conveyor speed, queue and tunnel activity, alerts, warnings and other important information at-a-glance on the new Tunnel Control Station’s integrated PC touchscreen.

- Screen border changes color when a condition arises that needs your attention

- Shows why a conveyor has stopped

- Indicators alert you when you’re on simulated pulse or simulated enter

- Displays easy-to-read override information right on the main screen

Additional Features

- Live Invoke – Make changes to tunnel equipment configuration while cars are in the tunnel without interrupting wash services

- Vehicle Traits Feature – Easily adjust conveyor equipment for different vehicle sizes and external features for less equipment wear and tear and better vehicle coverage

- Collision Avoidance – Supports two sensors located at the tunnel exit that detect if a vehicle pulls out early or if another vehicle is approaching too closely. Icons light up to convey messages and indicate when anti-collision has been activated.

- Device Saturation Guard – User-controlled configurations automatically cut off solutions like tire shine when enough chemical has already been applied to the device to handle the next vehicle

- Easily interface with SiteWatch® over the network without an SRMB or serial cable

- Simulated Pulse and Enter Switches – Keep TunnelWatch running smoothly when real switches fail

- Easy updates – Updates are completed remotely

- Cloud Backup – Includes automatic off-site backups, a simple one-step recovery process and the ability to reload prior configurations

Gain Even More Control

Add the following solutions to further fine-tune your tunnel performance.

Vehicle Profile Detection™

Uses sonar to profile vehicles to the inch and automatically identifies and adjusts for features like pickup truck beds without human intervention. This helps you minimize waste and deliver a better wash.

NoPileups by DRB Systems

Full-tunnel management system that uses advanced technology to help you increase capacity, identify broken or misaligned equipment and prevent costly and time-consuming collisions

Tunnel Control Station 2

The Tunnel Control Station 2 (TCS2) that runs TunnelWatch has been enhanced with state-of-the-art improvements to harness the power of TunnelWatch 5. The integrated, touchscreen PC allows you to manage the TunnelWatch software and view the new Quick Status Screen right from the tunnel controller while saving space in your office.

- Smaller footprint with expanded capacity – 6-function cards allow for 72 relays per enclosure

- Up to 16 inputs per TCS2 station

- Fan and vents, to help maintain temperature

- Relays individually fused, making it easier to diagnose and correct problems

- Ethernet interface and removable wiring blocks for easier wiring and connections

- Punchouts (with covers) for conduit eliminates the need for drilling holes

- Door is hinged for easy removal

- Enhanced integrated stop/start circuitry, allowing you to quickly determine which stop button was pressed